A granite measuring instrument is a precision tool crafted from solid granite, valued for its inherent stability and resistance to wear and temperature changes. It provides an ultra-flat, non-magnetic, and corrosion-resistant reference surface essential for highly accurate layout, inspection, and measurement tasks in quality control. This ensures reliable and consistent results when checking the straightness, flatness, or dimensions of critical parts.

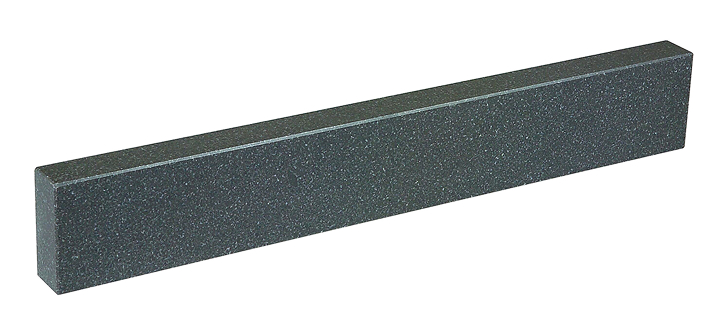

A granite parallel is a precision ground tool made from high-quality granite, providing an exceptionally straight and stable reference edge. Used primarily in inspection and layout work, it allows you to check the parallelism of parts, transfer precise measurements, and ensure components are perfectly aligned on a surface plate. Its wear-resistant and non-corrosive nature guarantees long- term accuracy and reliability for your most critical quality control tasks.

A granite square is a master precision tool that provides an exact 90-degree reference angle for inspecting the perpendicularity of parts and machines. Machined from a single piece of granite, itoffers exceptional stability and wear resistance, ensuring your measurements for squareness remain accurate and reliable over time. Its non-magnetic and corrosion-resistant properties make it an essential, maintenance-free tool for rigorous quality control environments.

A granite square ruler combines the function of a precision straightedge with an integral square,offering a reliable tool for both checking straightness and verifying perfect 90-degree angles. Crafted from solid granite, it provides a stable, wear-resistant, and corrosion-proof reference for accurate layout and inspection work on your surface plate, ensuring the perpendicularity of your critical components.

A granite straightedge is a master reference tool designed for checking the straightness and flatness of machine ways, surface plates, and other critical components. Its precision-ground edge provides an unwavering benchmark against which deviations can be accurately measured. Made from solid granite, it is inherently stable, resistant to wear, and will not corrode, guaranteeing long-term measurement integrity for your most demanding quality assurance applications.

Precision granite measuring tools, instrument bases are made of high quality “Taishan Black After fine grinding and hand lapping they are provided with high precision and long durability and suitable for measuring applications in factories and laboratories. “Taishan Black” mainly consists of pyroxene, plagioclase, biotite and micromagnitudes structure is hard and compact. It has solidified in a natural way over millions of years resulting in its homogeneity, reliable stability, high strength and super hardness. It can keep relatively high precision under heavy load.

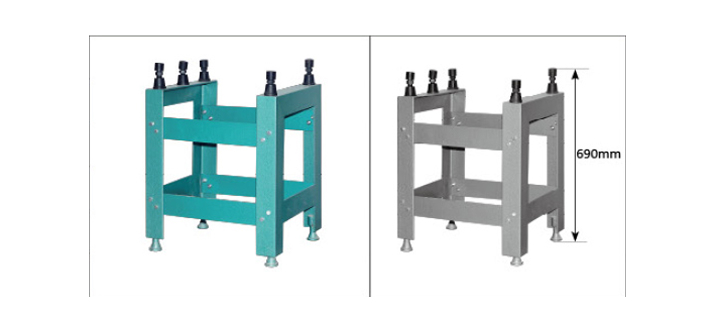

A granite surface plate stand is a heavy-duty, rigid support structure specifically engineered to provide a stable and vibration-free foundation for your precision granite surface plate. It is crafted to securely hold the plate at an ergonomic working height while isolating it from floor vibrations and thermal influences that could compromise measurement accuracy. This ensures your inspections and layout work are performed on a truly reliable and consistent reference plane.

A granite Vee block is a precision reference tool machined from a single piece of high-quality granite.It features a precisely ground V-shaped groove used to securely hold and align cylindrical objects like shafts, pins, or tubing for inspection, layout, or marking. Renowned for its exceptional stability, wear resistance, and non-corrosive properties, it provides a reliable and durable solution for maintaining accuracy in quality control and manufacturing processes.

Lorem ipsum dolor sit amet, consectetur elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar.