Category

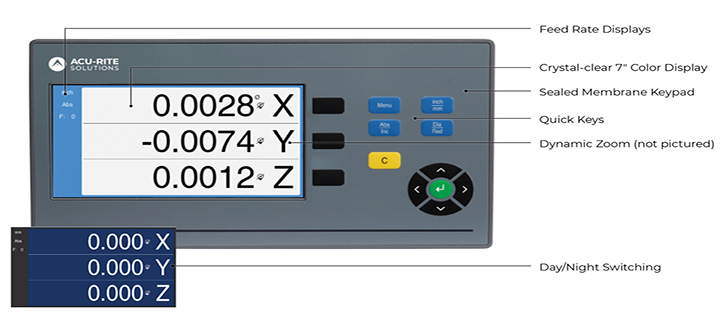

The DRO100 has basic features for milling, turning, grinding, and boring applications that require precisemachining and measurement. It continuously displays the true location of all axes, creating higher quality workpieces, less scrap, and tighter tolerances.

The DRO203 has pre-programmed common cycles plus milling and turning-specific functions that

continuously display the true location of all axes. This creates higher-quality machined workpieces, less

scrap, and tighter tolerances.

The Acu-Rite Solutions DRO203Q is a 2D geometric readout optimized for optical comparators and measuring microscopes. Powered by Quadra-Chek and backed by the continuous innovation of HEIDENHAIN, the DRO203Q measures 2D features with greater accuracy and efficiency. The DRO203Q has basic pre-programmed common cycles and metrology-specific functions for six different feature types. It provides extremely precise measurements, creating higher-quality workpieces, less scrap, and tighter tolerances.

Grow machine tool profitability with the most popular DRO. The Acu-Rite Solutions DRO300 is the most complete digital readout on the market. Backed by the continuous innovation of HEIDENHAIN, it improves the accuracy and efficiency of manual machine tools with up to four axes. Choose the IB2X option to allow up to six axes for large machine tool applications. The DRO300 continuously displays the true location of all axes through pre-programmed common cycles and milling and turning-specific functions. This creates higher-quality machined workpieces, less scrap, and tighter tolerances.

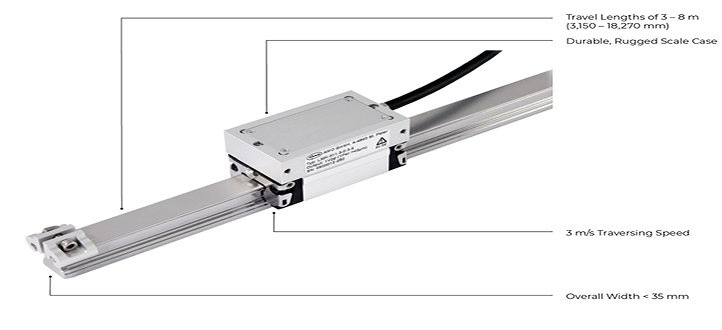

The LMF 9310 is a multi-section linear encoder that applies motion control innovations from HEIDENHAIN. It integrates an LMK scanning head, TTL incremental signals, and an inductive measuring tape clamped on a guide rail, making it virtually impervious to contaminants. The rugged construction of the LMF 9310 provides high-accuracy feedback and long-term durability. It is designed to improve machining quality while reducing costly errors, scrap, and downtime.

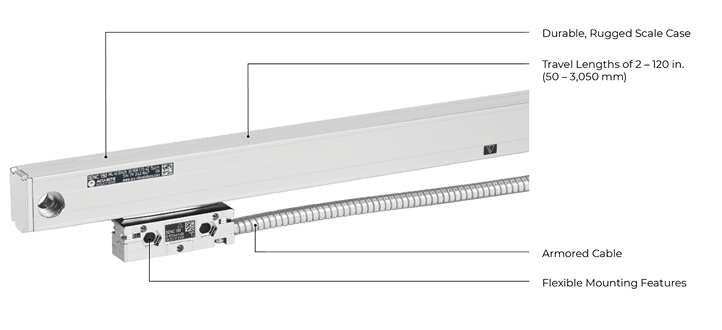

The SENC 150 is a versatile precision glass scale linear encoder with advanced precision technology from HEIDENHAIN. Its compact yet robust design reduces backlash, improves scale travel life, and provides high-accuracy feedback for EDMs, grinders, lathes, mills, inspection equipment, and beyond. The SENC 150 uses the reflected light method to increase machining accuracy, creating superior workpieces and time and cost savings. The glass resists size, shape, and density changes due to temperature and humidity variations.

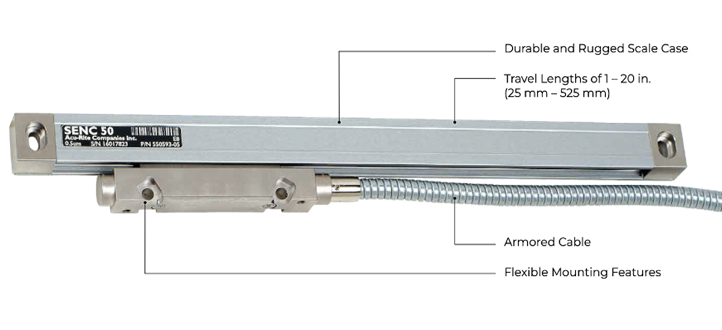

The SENC 50 is a compact linear encoder providing high-accuracy feedback in limited and restricted spaces. The precision glass scale resists size, shape, and density changes regardless of temperature and humidity variations, thanks to advanced optical technology developed by HEIDENHAIN. Better accuracy improves machining quality and time and cost savings. The SENC 50 features multiple resolutions with superior accuracy as well as Position-TracTM, which quickly recalls absolute zero (datum) after power loss.

Lorem ipsum dolor sit amet, consectetur elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar.